INNOVATION | EXPERIENCE

RELIABLE SOLUTIONS

Conveyor Dynamics, Inc (CDI)

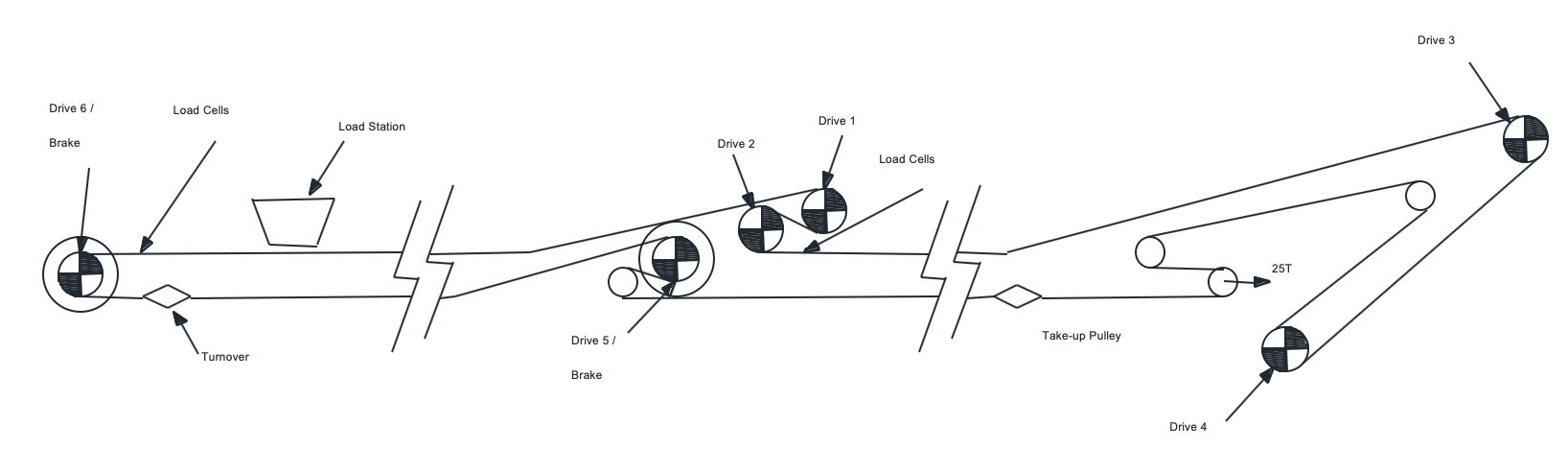

Born in 1981, CDI pioneered the use of dynamic analysis to design modern, long (> 2km), high capacity (> 10000 tph) overland and underground conveyor belts.

Not only do we design the longest and strongest belts in the world, our engineers create and sell the leading conveyor belt design software tools, the most reliable control systems, and develop improved belt, brake, and idler designs for manufacturers. We partner with the leading EPC and OEM's around the world to supply the most cost effective and reliable conveyors in every major market.

In additional to designing new machines, our engineers conduct forensic engineering studies to diagnose and fix failed conveyor belts. Our engineers understand the physics of conveyor belts, from the complete system, to the individual proportional brake valve better than anyone else in the world. If your conveyor is unreliable, CDI is here to change that.

World Records

Interesting facts

The numbers speak for themselves.

At CDI, we focus on the customer requirements to develop optimized overland systems where we use next-generation tools such as BeltStat, BeltFlex, PStress, ROCKY DEM, and ANSYS FEA.

OVERLAND BELT ENGINEERING

- Long length belts, curves, and bi-directional transport

- Standard, tubular, cable, and air suspended belts

- Structural optimization of belt path

- Pulley and Roller Analysis

- Tensioning system design

- Component specifications

- Advanced technology for conveyor belts

CONTROL AND START-UP

- Philosophy and advanced control logic

- PLC programming

- Specialized control of motors and brakes

- Control start and stop of head, tail and intermediate motor stations

- Tachometers, UPSs, and data acquisition systems (DAQs)

ROOT CAUSE ANALYSIS (RCA)

- Brake systems audit

- Optimization of torque transmission and load distribution of motors

- Evaluation and optimization of control algorithms

- Pulley and Splice Evaluation Using FEA Analysis

- Recording and Evaluation of the actual dynamic behavior of the belt

- Actual system torque measurement

OPTIMIZATION AND DESIGN OF CHUTES

- Chute geometry optimization with DEM software

- Granular flow simulations in chutes, feeders, trays, crushers and mills

- Capacity studies and bottlenecks

- Identification and resolution of root cause of blockages, spills, material degradation, dust, misalignment and wear of liners

- Material calibration